We give you options.

ARTAZN’s core expertise has always been creating the highest quality zinc strip from a variety of alloy compositions. That variety is key. We use 99.995% pure high-grade zinc to develop alloys through the precise and controlled addition of other metals, creating a family of alloys that tremendously expands our scope of applications.

We customize solutions to you.

The benefit of our family of alloys is four-fold: we can cater to more industries, particularly the coinage, automotive, building, and cathodic industries; consistently meet customers’ unique requirements; expand our customers’ product capabilities; and save our partners significant cost.

If any requested application falls outside our current scope, our product development team can work with customers to develop new alloys for new products. We are the largest zinc strip producer in North America and have in-house capabilities for melting, alloying, casting, rolling, slitting, and plating operations.

Explore the versatility

Our family of zinc strip alloys doesn’t end here. Contact us to discuss creating an Engineered Zinc Solution.

ZINC ALLOY 190

A copper hardened zinc alloy used for general purposes. Exhibits good strength and excellent ductility.

Typical Uses:

Coinage Products – ZincSecure® coin blanks

Building Products – Plumbing hardware, expansion joints, corner beads, and terrazzo strips

Automotive Products – Exterior trim

ZINC ALLOY 500

A soft material, copper hardened zinc alloy used for general purposes. Exhibits good strength and excellent ductility and formability.

Typical Uses:

Cathodic Protection Products – LifeJacket® and LifePanel®

ZINC ALLOY 505

A soft material, copper hardened zinc alloy used for general purposes. Exhibits good strength and excellent ductility and formability.

Typical Uses:

Building Products – Flashing.

ZINC ALLOY 600

A high-purity zinc alloy with extremely low levels of lead.

Typical Uses:

Specialty Products – Consumer goods applications: an additive for cosmetics, sunscreen, and paint.

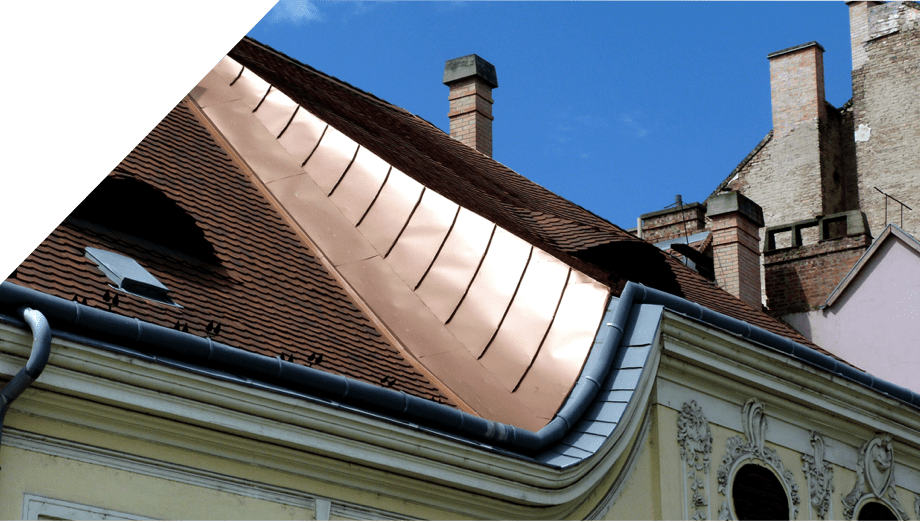

ZINC ALLOY 710

A copper and titanium alloy added to increase formability and strength.

Typical Uses:

Architectural Products – Roofing, wall cladding, dormers, steeples, and gutters.

Automotive Products – Blade fuses.

Building Products – Stained glass.

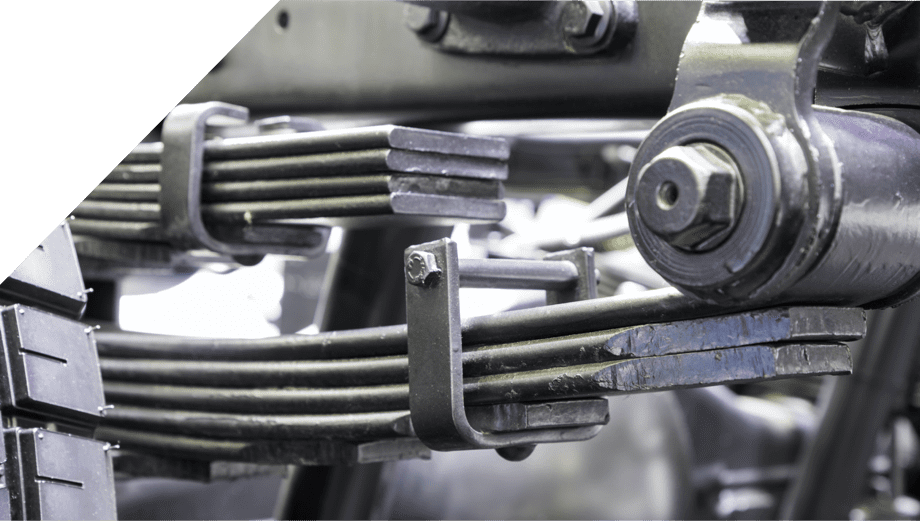

ZINC ALLOY 750

A copper and titanium alloy added for formability, conductivity differentiation, and strength.

Typical Uses:

Automotive Products – Blade fuses, low voltage terminals, and leaf spring inner-liners.

Trust our precision to promise you better performance.

Our manufacturing facility has one of the largest melting, casting, and rolling capacities in the world. We offer cut-to-length zinc sheets that are 27 inches (685.8 mm) wide and 215 inches (5461 mm) long.

We adhere to high-quality standards for our products and processes. We are an ISO 9001:2015 certified company and strive to provide excellent products for our customers.

Melting and Alloying

Our facility has one of the world’s largest zinc melting capacities that can alloy a diverse range of compositions.

Casting and Rolling

Depending on the zinc strip alloy, we roll the coil close to three-thousandths of an inch and slit according to the requirement.

Slitting

Our extensive zinc strip slitting and plating capacities give our customers a variety of widths and plating finishes that can help meet their market’s ever-changing demands.

Choose the perfect finish.

Each of our plating options has a purpose and an advantage, like improving aesthetics or increasing durability against extreme temperatures and humidity. Consult us for the right plating option for you.

ARTAZN also has the capability to plate small, stamped zinc parts such as coin blanks. To read more about our coin blank plating options, visit COINAGE.